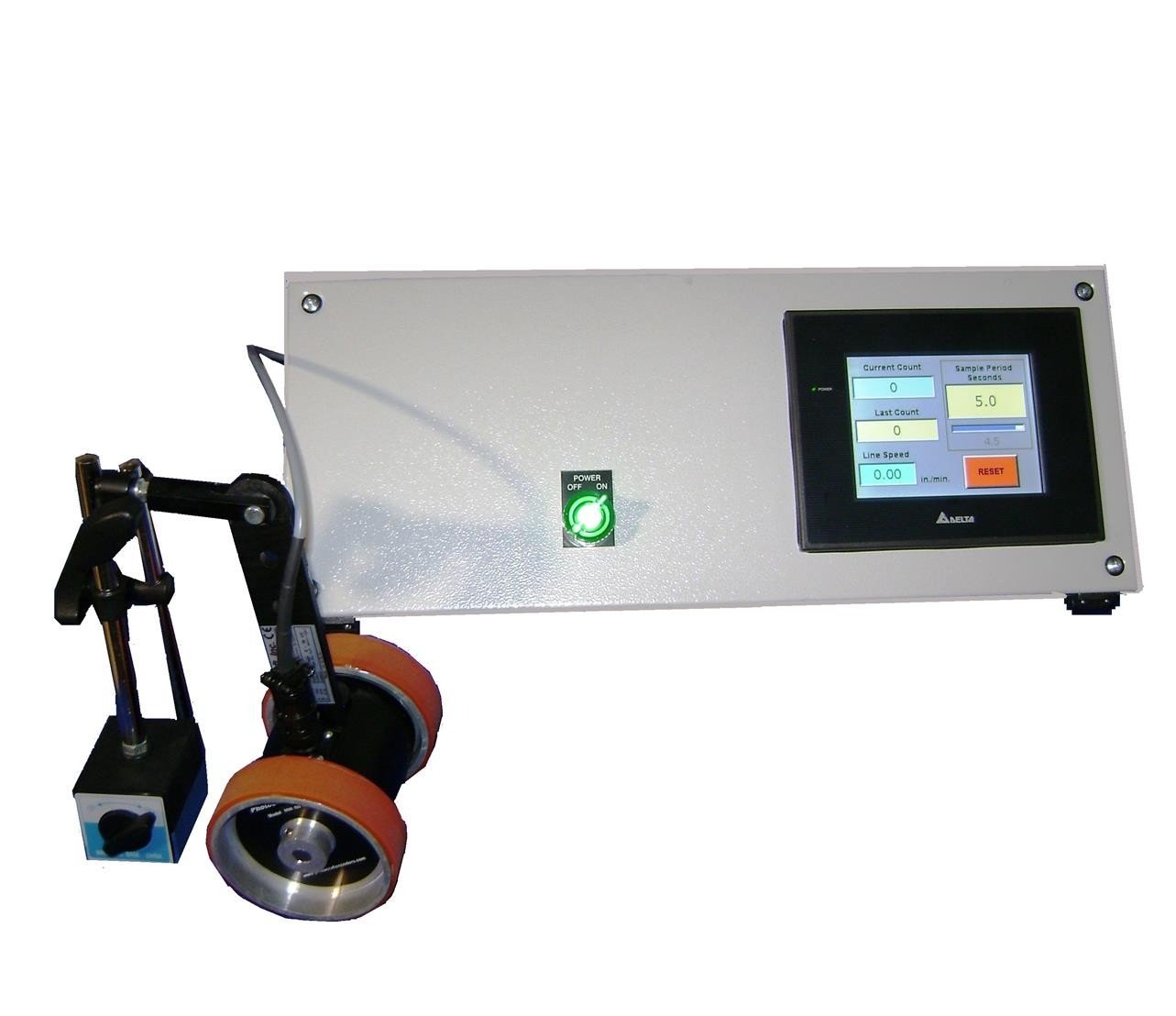

Do you need to transport products to conveyors at multiple heights? Do you need to load products into vertical storage racks and then retrieve them? If so, you’ll need a high-quality vertical lifting actuator, or lift station.

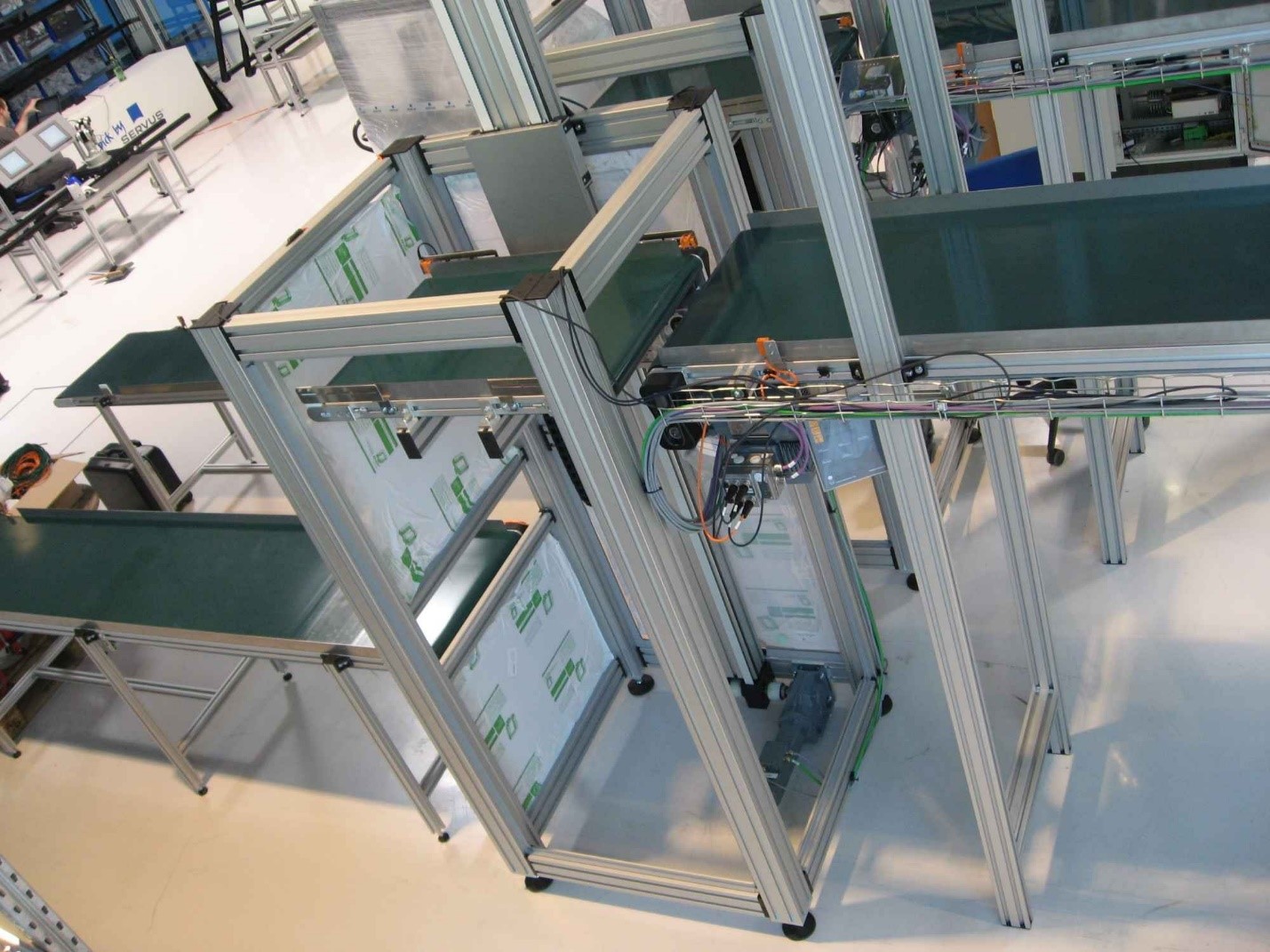

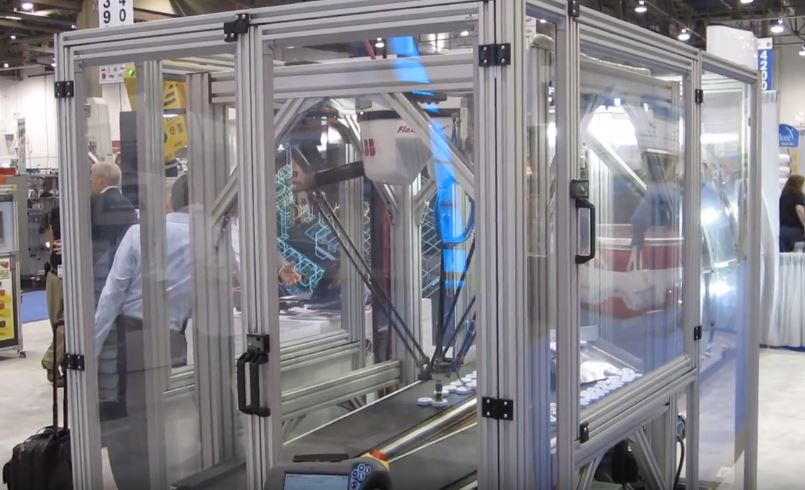

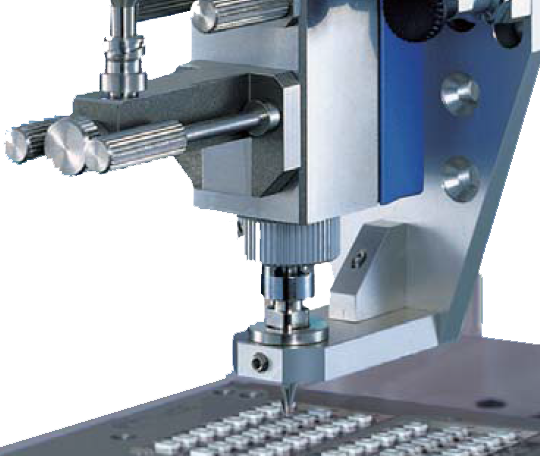

In our experience, Robotunits extruded aluminum lift stations are among the best solutions for multi-level product conveyance or storage requirements. Here’s what sets them apart: