The handling and guiding methods of carbon fibers to prevent filament damage or to maintain fiber width is often overlooked. However, it is an extremely important factor in carbon fiber production and downstream processing using carbon fiber and other high-performance fibers.

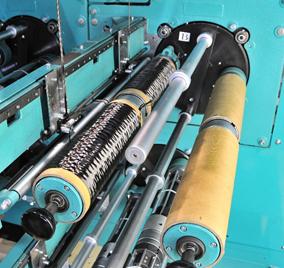

Redirection with sharp angles, use of guides without proper surface finish, excessive tension, static contact points: these are all factors that can induce damage to the filaments in the carbon fiber tow. Broken filaments not only degrade the strength of the carbon fiber, but also cause issues in processing leading to production downtime.

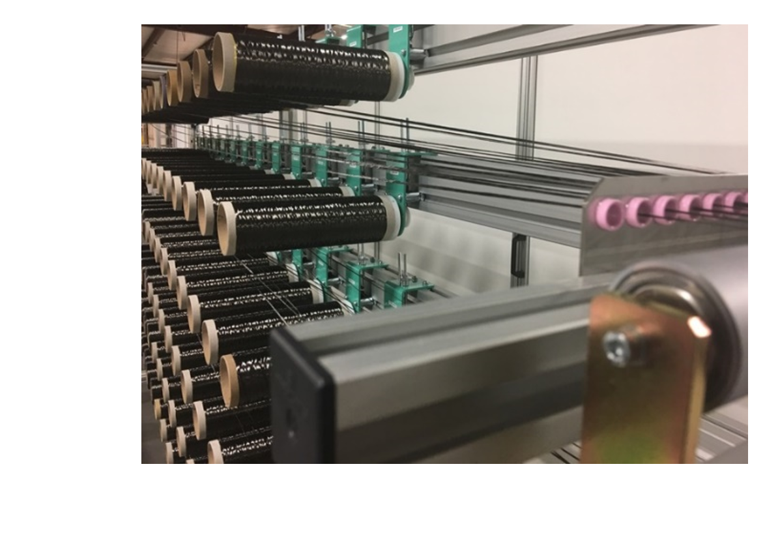

Broken filaments accumulate on rotating parts and will accumulate beyond containment, which not only needs an operator to intervene but can stop production or create defects in the product.

Fiber width can also be compromised when the proper guide elements or proper alignment methods are not used. Fibers can become narrower when false twists are induced, or if guide flanges physically case a fiber to narrow down. In some cases, the lack of sizing in the fiber can have negative effects on the fiber width. When using low sizing content fiber or un-sized fibers, the need to use of proper guiding elements is magnified greatly.

The main reason proper assessments are not made for fiber damage caused by inadequate handling is that there have been no quantitative means to measure fiber damage. Similarly, tools to maintain or monitor fiber width have not available. Read more to find out about tools to accomplish this and some analyzation studies.