Non-contact jet dispensers use a jetting mechanism to shoot fluids from a distance on to the substrate so that the nozzle does not need to be in close contact with the surface of the product. Jet dispensing is performed by high-speed dot pulsations from the nozzle, therefore single dot dispensing as well as line dispensing by connecting these dots is possible.

Non-contact jet dispensers use a jetting mechanism to shoot fluids from a distance on to the substrate so that the nozzle does not need to be in close contact with the surface of the product. Jet dispensing is performed by high-speed dot pulsations from the nozzle, therefore single dot dispensing as well as line dispensing by connecting these dots is possible.

Musashi Engineering is a global leader in fluid dispensing systems for automation, and their large selection of jet dispensers enables jetting for various materials with a wide range of viscosities.

Some benefits of jet dispensing are below:

- Faster cycle times due to elimination of z-axis adjustment

- Ability to dispense at any direction

- Enables dispensing in small cavities

- Part warping or part inconsistencies can be neglected

Watch this video showing some applications where the jet dispenser functionality

is most effective.

Are you having trouble meeting your required cycles times?

Do you have a part with inconsistent dimensional properties which prevent consistent dispensing?

Is the dispense target hard to access or are there physical obstacles in the way to get a needle close to the dispense area?

Do you use a jet dispenser having trouble dispensing a high viscosity fluid or have frequent missed shots or clogging in your existing jet dispenser?

Then a Musashi Engineering jet dispenser can be the solution. This guide below goes over various jet dispenser models available and the best application for each type.

Unique Benefits of Jet Dispensers

Z-axis flexibility:

Unlike traditional contact type dispensers, the fluid is jetted from a distance before making contact with the substrate. This means the gap between the nozzle to the substrate surface doesn’t need to be as precisely controlled. Therefore, the dispense accuracy is not compromised when working with uneven surfaces, and there is less a much smaller risk of scraping the target.

Speed:

The fastest jets have a frequency of over 1200Hz so dotting applications can be done at high speeds. Precise positioning in the z-axis is not required, so eliminating the z-movement also contributes to higher cycle times.

No nozzle contamination:

Non-contact dispensing is ideal for pharmaceutical applications because the nozzle never touches the surface of the substrate, meaning there’s no risk of contamination from one surface to another.

Reaching hard to access spots:

Jetting can be done from a distance, so fluids can be dispensed in hard-to-reach areas.

Below are some of the jet dispenser models and the benefits of each:

SuperHiJet

The SuperHiJet is capable of dispensing liquids with viscosities up to 1,000,000 cps with highly accurate location accuracy. Solder paste, epoxy resin, sealant, grease jetting applications are possible with this system. The SuperHiJet is capable of a maximum frequency of 500Hz. With an easy to access fluid delivery system, the SuperHiJet is a maintenance friendly jetting system. Watch the video here.

The SuperHiJet is capable of dispensing liquids with viscosities up to 1,000,000 cps with highly accurate location accuracy. Solder paste, epoxy resin, sealant, grease jetting applications are possible with this system. The SuperHiJet is capable of a maximum frequency of 500Hz. With an easy to access fluid delivery system, the SuperHiJet is a maintenance friendly jetting system. Watch the video here.

HyperJet2

The HyperJet2 was developed to jet the smallest volumes possible. Jet dispensing dots of 50-micron diameter has been achieved with Ag paste for the semiconductor industry. This jet is also equipped with a Peltier style nozzle temperature control system which enables accurate nozzle temperature control from 15°C to 80°C. See application examples here.

The HyperJet2 was developed to jet the smallest volumes possible. Jet dispensing dots of 50-micron diameter has been achieved with Ag paste for the semiconductor industry. This jet is also equipped with a Peltier style nozzle temperature control system which enables accurate nozzle temperature control from 15°C to 80°C. See application examples here.

Hot Melt SuperJet

The Hotmelt SuperJet is a variation of the SuperJet series dispensers and developed to jet hot melt glues and adhesives. The nozzle and supply syringe can be heated up to 180 degC to heat up the liquid. It is capable of jetting thin accurate lines which was traditionally difficult to do with hot melt type application. Watch the video here.

The Hotmelt SuperJet is a variation of the SuperJet series dispensers and developed to jet hot melt glues and adhesives. The nozzle and supply syringe can be heated up to 180 degC to heat up the liquid. It is capable of jetting thin accurate lines which was traditionally difficult to do with hot melt type application. Watch the video here.

Aerojet

The Aerojet is the most versatile jet dispenser with a wide viscosity range of 50 – 300,000 cps. Highest shot frequency is 333Hz, and the jet can be equipped with a nozzle heater also. Some applications include epoxy based underfill, solder paste jetting, UV curable resin jetting…etc. For more information, click here.

The Aerojet is the most versatile jet dispenser with a wide viscosity range of 50 – 300,000 cps. Highest shot frequency is 333Hz, and the jet can be equipped with a nozzle heater also. Some applications include epoxy based underfill, solder paste jetting, UV curable resin jetting…etc. For more information, click here.

CyberJet2

The Cyberjet2 is a jet dispenser developed specifically for low viscosity materials and have a range of 1 – 2,000 cps. Highest shot frequency is 133Hz, and the jet can be equipped with a nozzle heater also. Some applications include line dispensing for medical testing strips, jetting of solvent based fluids, other bio and pharmaceutical applications…. etc. Watch the video here.

The Cyberjet2 is a jet dispenser developed specifically for low viscosity materials and have a range of 1 – 2,000 cps. Highest shot frequency is 133Hz, and the jet can be equipped with a nozzle heater also. Some applications include line dispensing for medical testing strips, jetting of solvent based fluids, other bio and pharmaceutical applications…. etc. Watch the video here.

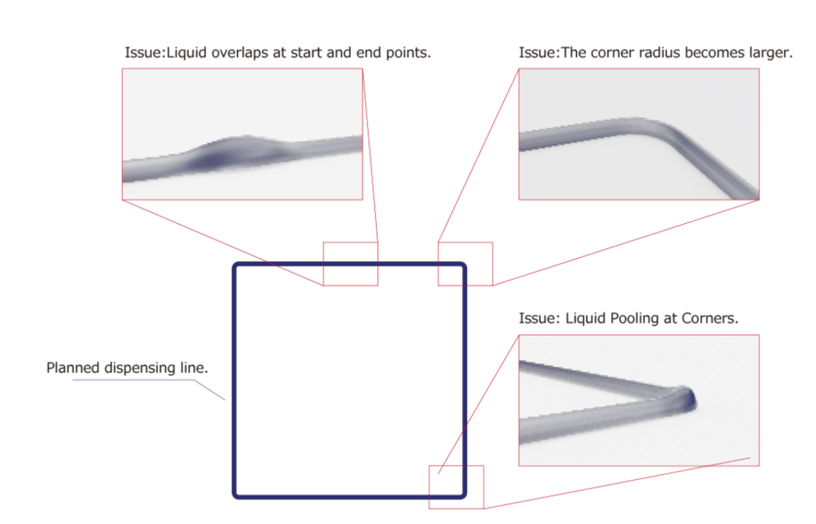

Synchro-Speed Function for Jet Dispensers

All Musashi Engineering jet dispensers used with Musashi Engineering robot systems can utilize the patented SynchoSpeed function. This unique function enables the dispenser to communicate with the robot so that dispensing line widths are kept consistent through corners or start-end points where dispensing can overlap. The dispenser increases or decreases dispense volumes based on the robot’s speed adjustment, so that the dispenser line width is maintained (see picture below). Watch the video here.

Not exactly sure which solution you need, or starting from scratch on a new automation line? Contact our experienced engineers for custom solutions tailored to your particular needs.