The Robotunits conveyor line has a wide range of conveyors to accommodate any application

with a various range of widths, lengths, and belt types.

In addition to standard conveyance of parts or materials, accumulating, vacuum, magnetic conveyors, and custom conveyors outside of the standard dimensions are also available.

Conveyors equipped with PLC systems are also available to perform customized automated tasks. These systems are supplied with development software so that the end user can adjust the logic as required.

The conveyor systems are seamlessly integrated into the Robotunits aluminum extrusion system: The extrusions and fasteners used in the conveyors systems are the same as the framework, making integration into equipment structures very easy.

There are a variety of conveyors in the lineup as shown below:

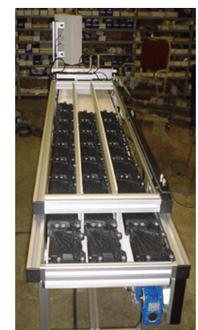

Double Deck Conveyors

The two decks of conveyors can be programmed in either direction, making these conveyors ideal for processing and return conveyors for assembly of parts, while doubling as an accumulation conveyor. An operator HMI can be equipped for more complicated processes requiring operator interaction with the conveyor. Part presence sensors can be equipped to index the conveyor as the parts are loaded to the conveyor, for semi-automated processes.

The two decks of conveyors can be programmed in either direction, making these conveyors ideal for processing and return conveyors for assembly of parts, while doubling as an accumulation conveyor. An operator HMI can be equipped for more complicated processes requiring operator interaction with the conveyor. Part presence sensors can be equipped to index the conveyor as the parts are loaded to the conveyor, for semi-automated processes.

Inspection and Storage Conveyors

Inspection/storage conveyors are used when inspection of a part is required and accumulated for storage after the product passes inspection. Inspection method can be by camera system or simple proximity switches, depending on the application. If the inspection is unsuccessful the product will be sent to a reject bin, whereas successful parts will be accumulated on the conveyor. Multiple lane conveyors are possible when the storage capacity needs to be increased.

Programmable Conveyors

These conveyors are equipped with a customer configurable PLC for programming the conveyor for simple tasks. The development software is provided with the conveyor so that modifications can be made by the end user to adjust the conveyor sequence or repurpose the automation for future projects. The PLC is equipped with external I/O to allow implementation of part presence sensors, push buttons…etc.

These conveyors are equipped with a customer configurable PLC for programming the conveyor for simple tasks. The development software is provided with the conveyor so that modifications can be made by the end user to adjust the conveyor sequence or repurpose the automation for future projects. The PLC is equipped with external I/O to allow implementation of part presence sensors, push buttons…etc.

Standard Belt Conveyors

Robotunits offers the highest quality and a wide range of conveyor belts as well as great flexibility in drive options and positions. The available speed ranges from 2.6 to 67 m/min and the standard widths available are width 40 to 1200 mm.

Robotunits offers the highest quality and a wide range of conveyor belts as well as great flexibility in drive options and positions. The available speed ranges from 2.6 to 67 m/min and the standard widths available are width 40 to 1200 mm.

Learn more about belt conveyors.

Modular Belt Conveyors

Robotunits offers service-friendly, modular belt conveyors that can be tailored to your exact requirements. Multiple widths, lengths, speeds, and sizes are available, and belts can be straight, curved, or on a gradient to create the perfect fit for your process. These conveyors are especially good for accumulation systems and conveying requiring curves and turns.

Robotunits offers service-friendly, modular belt conveyors that can be tailored to your exact requirements. Multiple widths, lengths, speeds, and sizes are available, and belts can be straight, curved, or on a gradient to create the perfect fit for your process. These conveyors are especially good for accumulation systems and conveying requiring curves and turns.

Learn more about modular belt conveyors.

Timing Belt Conveyors

For the transport of bulky and heavy parts, Robotunits offers the C4T and C8T timing belt conveyor. Standard lengths up to 12 meters are available. For this conveyor, a special, self-tracking timing belt that better withstands lateral forces than conventional belt is used. Parts travel on conveyor safely and smoothly since any interfering edges are removed. With the Robotunits timing belt, conveyor indexing and positioning applications are easily implemented conveniently and economically. Robotunits offers a wide range of different belt surfaces and profiles.

For the transport of bulky and heavy parts, Robotunits offers the C4T and C8T timing belt conveyor. Standard lengths up to 12 meters are available. For this conveyor, a special, self-tracking timing belt that better withstands lateral forces than conventional belt is used. Parts travel on conveyor safely and smoothly since any interfering edges are removed. With the Robotunits timing belt, conveyor indexing and positioning applications are easily implemented conveniently and economically. Robotunits offers a wide range of different belt surfaces and profiles.

Learn more about timing belt conveyors.

Karakuri Type Conveyors

Karakuri automation systems require no electricity or electronic controls, utilizing the weight of the product itself to generate motion. It is a low-cost solution for automated material handling. Systems are custom designed to accommodate each application.

Karakuri automation systems require no electricity or electronic controls, utilizing the weight of the product itself to generate motion. It is a low-cost solution for automated material handling. Systems are custom designed to accommodate each application.

Learn more about Karakuri Automation

Powered Roller Conveyors

These powered roller conveyors enable automated material handling. They are powered by 24VDC and utilized modular control boards. The multi-faceted system is ideally suited for zero-pressure accumulation conveying of goods, boxes or other containers in industrial applications.

These powered roller conveyors enable automated material handling. They are powered by 24VDC and utilized modular control boards. The multi-faceted system is ideally suited for zero-pressure accumulation conveying of goods, boxes or other containers in industrial applications.

Lift Stations for Conveyors

Do you need to transport products to conveyors at multiple heights? Do you need to load products into vertical storage racks and then retrieve them? If so, you’ll need a high-quality vertical lifting actuator, or lift station. In our experience, Robotunits extruded aluminum lift stations are among the best solutions for multi-level product conveyance or storage requirements.

Do you need to transport products to conveyors at multiple heights? Do you need to load products into vertical storage racks and then retrieve them? If so, you’ll need a high-quality vertical lifting actuator, or lift station. In our experience, Robotunits extruded aluminum lift stations are among the best solutions for multi-level product conveyance or storage requirements.

Storage and Feeder Hopper Conveyors

The storage and feeder hopper conveyors from Robotunits are the modular solution for the precise feeding of bulk materials and dimensionally stable parts. Based on the C4N belt conveyor, flexibly adaptable in height, width and incline - for fast and economical integration into any process.

The storage and feeder hopper conveyors from Robotunits are the modular solution for the precise feeding of bulk materials and dimensionally stable parts. Based on the C4N belt conveyor, flexibly adaptable in height, width and incline - for fast and economical integration into any process.