If you’re involved in LED manufacturing, you understand how much relies on your equipment providing exact accuracy each time. You want to avoid wasteful mistakes while creating LED products that are perfectly consistent from production day to production day.

If you’re involved in LED manufacturing, you understand how much relies on your equipment providing exact accuracy each time. You want to avoid wasteful mistakes while creating LED products that are perfectly consistent from production day to production day.

Unfortunately, some of the more finicky steps of LED production pose challenges for consistency. This is especially true in the case of the potting of phosphors for white LEDs.

The challenges of dispensing white-light phosphors

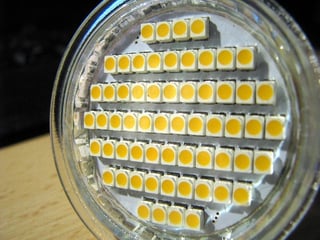

The typical potting mixture applied over blue LEDs to create white light consists of three or four types of phosphor powders set within two or more types of silicone resin. Variations in the ratios of these ingredients (plus silicone’s high elasticity) mean that the viscosity of the mixture may range anywhere from 2000 to 8000 cps.

In addition, the mixture’s texture changes over a short amount of time, meaning the viscosity at the beginning and end of the dispensing session can be very different.

These fluctuations can cause major problems for traditional pneumatic dispensers. Stringing of the fluid becomes a problem as the viscosity increases, air bubbles can get mixed in with the fluid (particularly with air-jet dispensers), and it’s difficult to control the accuracy and consistency of dispensing when dealing with such small volumes.

A dispenser designed for LED manufacturing

Knowing the challenges LED producers face, the engineers at Musashi created a volume-control dispenser designed specifically for LED potting. The Measuring Master MPP-1 dispenses fluids based on the actual volume or weight of the fluid, not its viscosity. The ultra-precise, plunger-style dispensing control also prevents air contamination, and the digital controller can set dispensing amounts to as small as 0.00001 mL, allowing for high levels of precision.

The Measuring Master has already been adopted by several major players in the LED manufacturing world. You can see the dispenser in action in this behind-the-scenes video for Nanoleaf brand LED lighting (footage starts at 0:41):

To learn more, visit the MPP-1 dispenser product detail page, where you can find technical specifications and view the product brochure.

More LED manufacturing solutions

If you’re setting up a new LED manufacturing production line or planning to put in dispensing equipment for an R&D process and would like recommendations on equipment that will work efficiently and cost effectively, contact our engineers. We’ll be happy to walk you through the best available products or even create a customized solution for you.