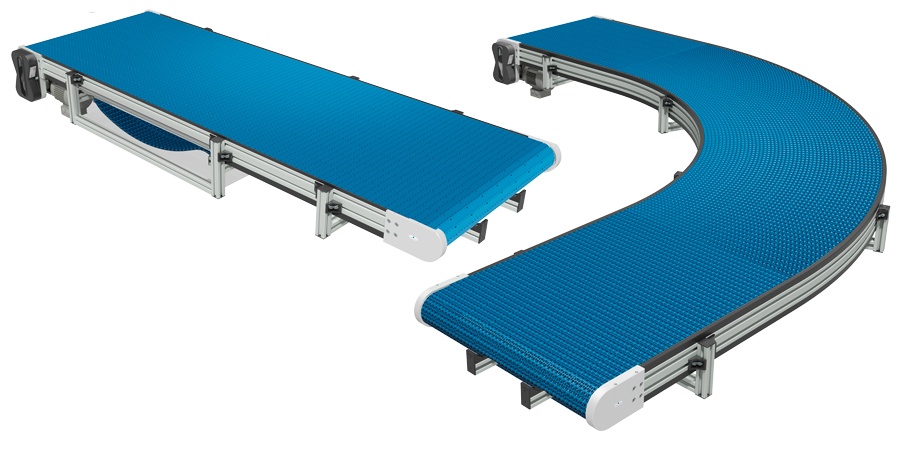

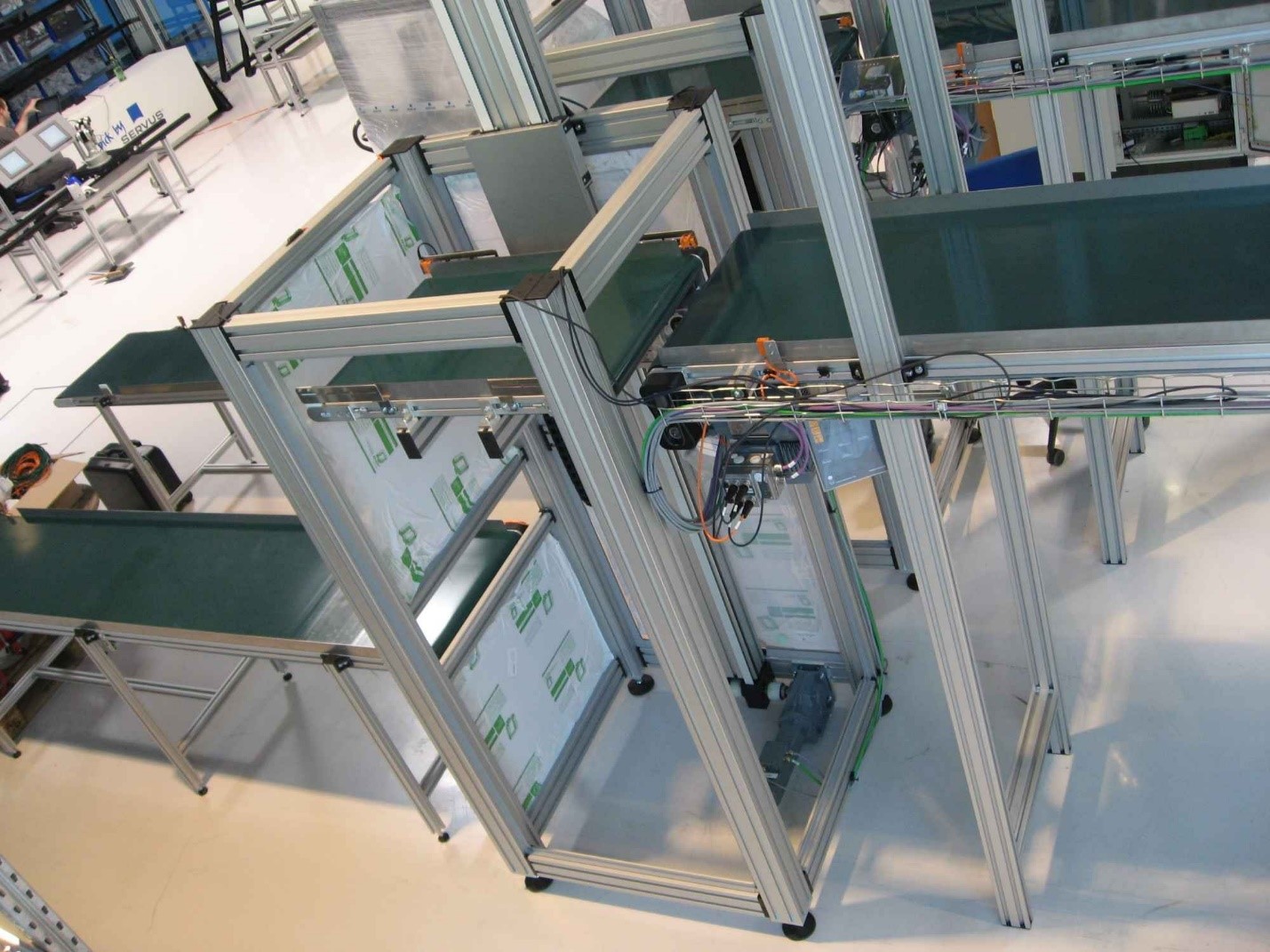

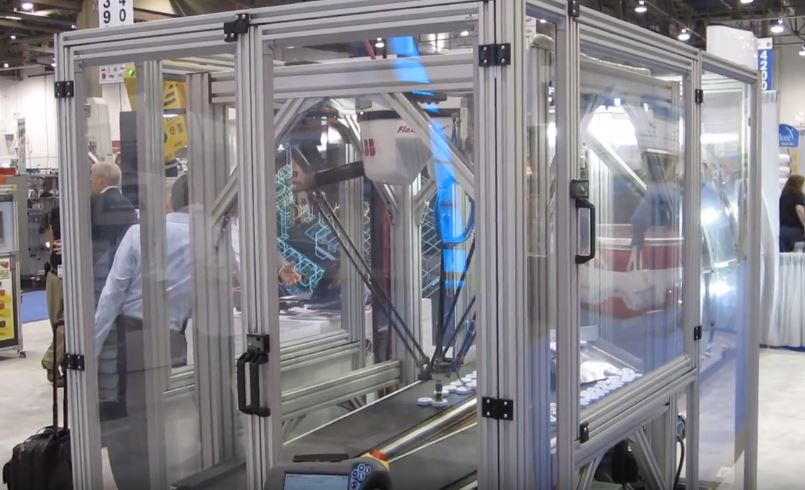

This month’s blog post focuses on our Powered Roller Conveyors. These plug-and-play conveyors transport containers, totes, and boxes with precision and efficiency in straight, curved and 90-degree directions and are ideal for zero-pressure accumulation. You can also control each zone separately.

There are several options to choose from:

- Powered Roller Conveyors. Available in straight and curved models, these units integrate a 24-volt drive and galvanized steel rollers.